Eco-Friendly Tools

Common Mistakes to Avoid When Using Gas Tools

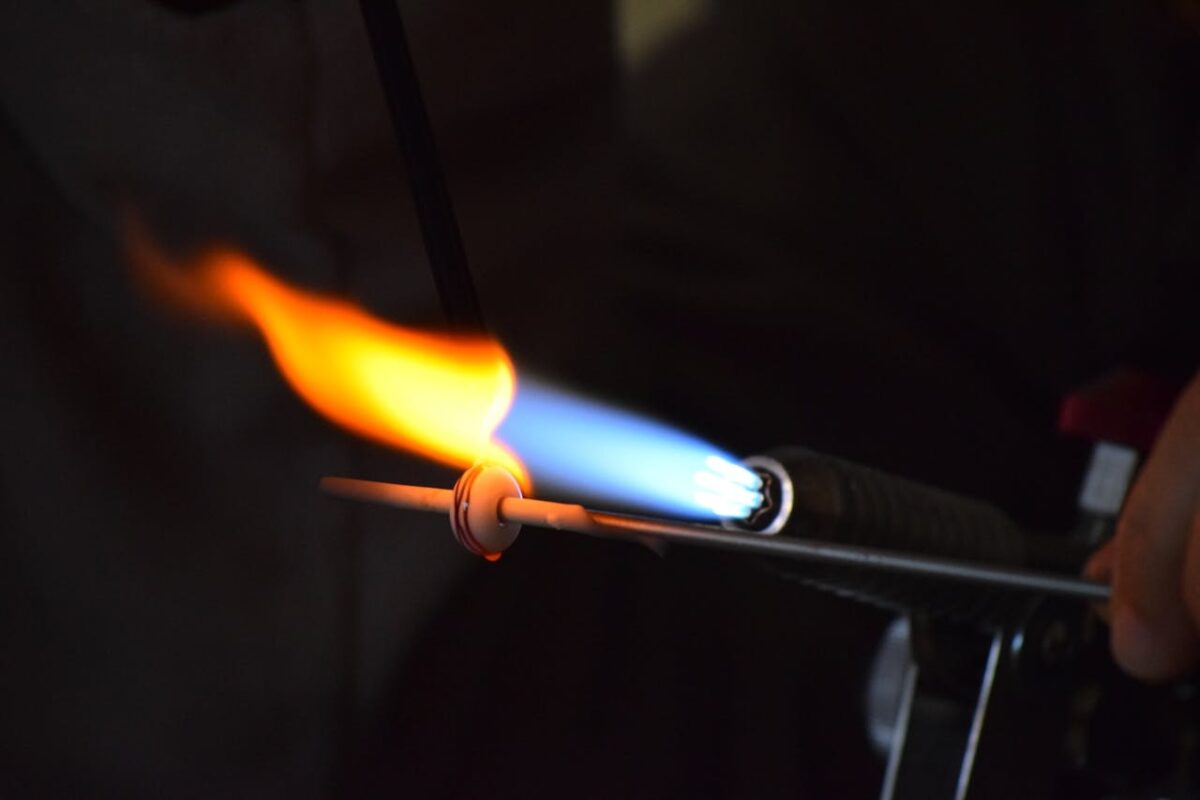

Using gas tools can make many projects easier, but it’s important to use them correctly to avoid mistakes. When you skip safety steps or don’t handle the tools properly, you can put yourself and others at risk. Knowing what to avoid can help you use gas tools safely and effectively.

One common mistake is not wearing the right safety gear. Gloves, goggles, and masks are essential when working with gas tools. These protect you from burns, flying debris, and harmful fumes. Ignoring safety gear can lead to serious injuries that are easily preventable.

Improper fuel handling is another area where mistakes are often made. Safe refuelling practices are crucial to avoid spills and fires. Storing fuel incorrectly can also be dangerous. By following the right steps, you can keep yourself safe and your tools ready to use.

It’s also important to operate the tools correctly. Many people skip reading the manual or assume they know how to use the tool. This can lead to misuse and accidents. Understanding how your tool works and avoiding common operation mistakes will help you work more efficiently.

Finally, regular maintenance of your tools is key to keeping them in good shape. Skipping inspections or not cleaning your tools can cause them to wear out faster, leading to breakdowns or unsafe conditions. With regular care, your gas tools will last longer and work better.

By avoiding these common mistakes, you can ensure that your projects go smoothly and safely. Proper use and maintenance of gas tools are essential for achieving the best results in any task.

Skipping Safety Gear When Using Gas Tools

Wearing safety gear is crucial when working with gas tools. Items like gloves, goggles, and masks protect you from various hazards. Gloves provide a solid grip and shield your hands from burns and cuts. Goggles protect your eyes from flying debris, sparks, and fumes. Masks help you avoid inhaling harmful particles and gases that can be released during use.

Not wearing proper safety gear can lead to serious injuries. Without gloves, you risk burns or blisters from hot surfaces and chemicals. Skipping goggles can result in eye injuries from sparks or debris. Not using a mask can cause respiratory issues, especially when working in enclosed spaces. By always wearing the appropriate gear, you significantly reduce your risk of injury and ensure a safer working environment.

Improper Fuel Handling

Handling fuel correctly is essential to avoid accidents. Here are some tips for safe refuelling:

1. Turn Off the Tool – Always make sure your gas tool is turned off before refuelling. This prevents accidental ignition.

2. Refuel Outdoors – Refuel in a well-ventilated area or outdoors to avoid inhaling fumes and reduce fire risk.

3. Use Proper Containers – Store and transport fuel in approved containers designed for gasoline to prevent leaks and spills.

Common fuel storage mistakes can lead to dangerous situations. One mistake is storing fuel indoors or near flames, which can cause fires. Another mistake is using unsafe containers, which might leak. Avoid overfilling the tank as well, as this can lead to spills that can ignite. By following proper fuel handling and storage guidelines, you keep your workspace safe and your tools ready to use.

Incorrect Tool Operation

Reading the manual thoroughly is essential when using gas tools. The manual provides specific instructions on how to operate the tool safely and effectively. Skipping this step can lead to misuse and accidents. Each tool is different, and understanding its unique features and operations can help you avoid mistakes.

Common operation errors include using the wrong settings, not securing the tool properly, or working in unsafe conditions. For instance, using too much or too little pressure can damage the tool or the material you’re working on. Always check the settings and ensure you’re using the tool as intended. Operating gas tools in poorly ventilated areas can also be harmful due to fume build-up. By adhering to the guidelines provided in the manual, you can avoid these mistakes and ensure smooth operation.

Neglecting Regular Maintenance

Regular tool inspections are crucial to ensure your gas tools remain in good working order. Inspecting your tools before and after use can help you spot any issues early, such as wear or damage. This can prevent accidents and prolong the life of your tools. Look for any signs of rust, wear, or loose parts that need tightening.

Cleaning and storing tools properly is also important. After each use, clean your tools to remove any dirt, dust, or residue. This keeps them functioning efficiently and prevents build-up that could cause malfunctions. Store your tools in a dry, cool place to avoid rust and damage. Use storage containers or racks to keep them organised and accessible. By maintaining your tools regularly, you ensure they are ready for use when needed and avoid any unexpected breakdowns.

Conclusion

Using gas tools can be very rewarding when done right. By avoiding common mistakes, you can work more efficiently and safely. Always wear proper safety gear to protect yourself from potential hazards. Handle fuel correctly to avoid spills and fires. Make sure to read the manual thoroughly and follow operation guidelines. Regular maintenance and inspections keep your tools in top shape.

Remember, taking these precautions not only protects you but also extends the life of your tools. It’s important to be mindful of the way you use and care for your gas tools. This attention to detail ensures that your projects will be successful and enjoyable.

If you’re looking to get the best out of your gas tools, explore the range of high-quality products, including gas burner cylinders, at Bernzomatic. Stay safe and efficient with our reliable tools. Visit Bernzomatic today to enhance your DIY experience!